Thank You

22642 N. 15th Ave. Phoenix AZ 85027 USA

Begejstret viste jeg for et par måneder siden, på linket her forhold om en sjælden type stempelringe kaldet Total Seal, som jeg havde fundet frem til, og monteret på min mc.

Stempelringsættene fra Total Seal piston rings gav ikke umiddelbart problemer, en moderat mængde røg fra nyrenoverede motorer kan forventes, men fra min forblev det for meget. Det ville jeg ikke køre med.

Efter et par måneder hvor at jeg gennemgik og forsøgte alle muligheder for at mindske dens smøreolieforbrug, da opgav jeg at køre med Total Seal stempelringene. Jeg stod ikke alene med dårlige erfaringer fra Total Seal stempelringe, ved søgninger i fora om disse interessante stempelringe findes rigtig mange indlæg fra skuffede brugere, jeg var led ved at have en blå røghale efter mc'en, periodisk var det værre end som fra knallerter eller mc'er med 2-takt benzinmotorer.

Jeg indstillede mig på at klodse mc'en op, indtil at jeg så fik råd til at købe nye motordele. Efter et par dage fik jeg dog energi til at sætte et par ord sammen til firmaet Total Seal, om mine erfaringer med deres produkt. Jeg gengiver dialogen herunder, ikke kun fordi at der som indledningsvis nævnt er andre muligheder, men fordi at der faktisk under dialogen viste sig at tildels jeg, og mest forbløffende, folkene fra stempelringsfirmaet Total Seal, ikke var helt klar over en meget vigtig detalie ved stempelringe.

Original Message -----

Did you happen to use a surface roughness tester on the cylinders? If so what Ra, Rpk, Rvk did you have? The liner hardness is what dictates the stone grit and type, ie Silicon carbide or alumimum oxide.

About the first question I can answer better tomorrow.As inlet valve, inlet valve guide and Viton seal are new, I determine oil was from the rings. Is there other ways to determine that?In fact I have had in mind, to increase the pre-tension of the oil scraper rings, by strechting the center part of oil ring, but now I dont think that it is enough. Furthermore I have read, that the napier shape on tradition 2. ring, in practice is more important to low oil consumtion, than the oil rings.In the complete sets you did send me was the 2. rings cast iron. Perhaps these are good to enshure seating, but gives smoke on mc-engines. Do you think you have napier shape rings to 2. grooves that are worth one more attempt?Yours faithfullyKurt Christian Aggesen

Original Message -----

I show the oil ring to be the correct tension for a 2.755 bore. I can build a napier ring. The cost is 9.50 dollars each. I would suggest a 280 grit hone.

Then I try such four napier rings. Instead of 2.755 make them to a 2.76 bore, this is 70,1 mm. and what I ordered. About the napier shape, specialists of today calls it a oil reservoir, but I think the napier shape more works as a plough or return thrower, and that is nessecary to understand the design. Will they be of cast or steel?Yours faithfullyKurt Christian Aggesen

can do a 2.755 ring or a 2.775 ring for the napier. Please advise

I have transferred $100.45 to your mailadress via paypal.The contact area of the piston rings to cylinder surface, specially of napier rings is quite small and by that with a relatively high area pressure, my opinion is that the wear resistance of cast iron is much insufficient, and of that reason is better when the napier rings are made of steel? Because the oil return throwing effect, between piston skirt and cylinder, is depending on the napier shape?Yours faithfullyKurt Christan Aggesen

Most of the 2nd rings are a cast material. The rings are a shallow radial or they are back cut to reduce the tension on the point. Napiers have been around for a long time. If we do a steel it has much more tension.

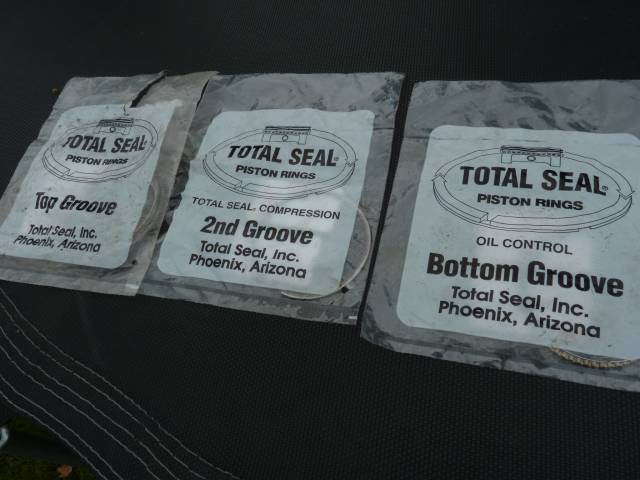

Herover et billed med forskellige typer af stempelringe. Egentlig bestilte jeg kun et sæt gapless top ringe til hvert stempel, men Total Seal ville kun sælge komplette sæt til hvert stempel, det gik jeg med til idet at jeg derved kunne være mere sikker på at få det til at virke, dvs. sættene indeholdt "cast 2. rings" . Ringene er afmærkede så at man kan være sikker på at vende dem rigtigt, selve formen på 2. ringene var jeg ikke helt opmærksom på, jeg er ret sikker på at deres udvendige vinkler var 2 stk. rene og skarpe 90 grader, mage til som vist ovenfor som torsional, ihverttilfælde er 2. ringenes anlægsflade mod cylinderne parallel, her efter tilkørslen.Ved den erfaring jeg fik med det første sæt ringe, med alt for højt smøreolieforbrug, da vil jeg tilmed have tendens til at diskvalificere taper face ringe som 2. ringe, idet at olieafstrømningen derfra går vinkelret og med højt tryk ind i bunden af stempelringsporet og kan derved passere bagom ringen. Napier formen forekommer som en grundlæggende forudsætning på 2. stempelringene. Men det har selv folkene hos Total Seal åbenbart ikke være opmærksomme på. -bevares, det almindelige svar angående for stort olieforbrug, det er at olieringene så må være defekte, enten slidte eller har mistet deres forspænding. Dvs. de nederste ringe, olieskraberingene, deres opgave er så mere en fordeling af olien hele vejen rundt på cylinderfladen. Nå, de nye stempelringe er først undervejs, men der er da lidt grund til at være optimistisk.Med venlig hilsenKurt Aggesen, d. 07.05.2013.Den 27.05.2013: Så fik jeg monteret det nye sæt 2. stempelringe, som Total Seal fremstillede til mig. Så det var med nogen forventning om mindre olieforbrug og mindre røgudvikling fra motoren, at motoren kom igang igen. Resultatet var klart, nu er olieforbruget minimalt, og røgudviklingen tilsvarende lav. Her vil jeg ikke sidde og fremstille mig som en der gør sig mere klog og vide mere om et specialprodukt, end hvad producenten selv bør besidde, uden også at dokumentere påstanden. Dette faktum ses reelt af foregående dialog, at den manglende viden hos producenten også har været en hæmsko for udbredelsen af deres produkt kan man iøvrigt se af en lang række debatindlæg derom. På billedet ovenfor ses emballagerne: De kalder nederste sæt stempelringe "OIL CONTROL", tilsvarende som vi kalder dem olieskraberinge. Men i virkeligheden da overfortolkes den funktionsmæssige betydning af ordet oil control eller olieskraberinge, og det faktum kan jeg underbygge således: Ifølge faglitteraturen oplyses at oliekanalerne der går fra bunden af olieringsporet skal være åbne og frie for koksaflejringer, så at olien fra olieskraberingene kan udledes i bunden af stemplet. Koksaflejringer der kan sikkert opstå ved meget koksbelastet olie eller hvor at stempelringene er så slidte og utætte, så at kompressionstrykket afsætter koks der. Men i virkeligheden da tilledes bunden af stemplet og stempelhulheden smøre/køleolie ved krumtapsølernes rotation. Således kan oliens retning i stemplets kanaler ligesom vel være ud mod cylindervæggen, hvor olieskraberingenes funktion så er en fordeling af olie rundt på cylinderfladen.Herover ses en af stempelringene som Total Seal i 2. omgang fremstillede til mig: "Napier shape" sporet, krog- eller plovsporet ses her tydeligt, på stemplet skal ringen vendes så at dette spor vender ned mod bunden af stemplet. Jeg antager endvidere, at selve udformningen af dette spor også har betydning, idet at det ideelle vil være at afkastedybden tilpasses stemplets yderdiameter eller stempel/cylindertolerancen, for at sikre at der ikke opbygges et olietryk indvendigt i ringsporet.Således en mængde konstruktiv information om Total Seal stempelringene, hvorhos en alvorlig fejl nu må være afdækket. Jeg kan nu anbefale disse stempelringe, ud fra de giver motoren forbedret kompression og mindre varmebelastning, fordi at der ikke trykkes gas ned mellem cylinder og stempel, dette er fakta som kan registres her kort tid efter ibrugtagningen. Det interessante bliver så at erfare om den flerdobbelte holdbarhed eller levetid opnås dermed.Mvh. Kurt Aggesen d. 27.05.2013

Her vil jeg ikke sidde og fremstille mig som en der gør sig mere klog og vide mere om et specialprodukt, end hvad producenten selv bør besidde, uden også at dokumentere påstanden. Dette faktum ses reelt af foregående dialog, at den manglende viden hos producenten også har været en hæmsko for udbredelsen af deres produkt kan man iøvrigt se af en lang række debatindlæg derom. På billedet ovenfor ses emballagerne: De kalder nederste sæt stempelringe "OIL CONTROL", tilsvarende som vi kalder dem olieskraberinge. Men i virkeligheden da overfortolkes den funktionsmæssige betydning af ordet oil control eller olieskraberinge, og det faktum kan jeg underbygge således: Ifølge faglitteraturen oplyses at oliekanalerne der går fra bunden af olieringsporet skal være åbne og frie for koksaflejringer, så at olien fra olieskraberingene kan udledes i bunden af stemplet. Koksaflejringer der kan sikkert opstå ved meget koksbelastet olie eller hvor at stempelringene er så slidte og utætte, så at kompressionstrykket afsætter koks der. Men i virkeligheden da tilledes bunden af stemplet og stempelhulheden smøre/køleolie ved krumtapsølernes rotation. Således kan oliens retning i stemplets kanaler ligesom vel være ud mod cylindervæggen, hvor olieskraberingenes funktion så er en fordeling af olie rundt på cylinderfladen.Herover ses en af stempelringene som Total Seal i 2. omgang fremstillede til mig: "Napier shape" sporet, krog- eller plovsporet ses her tydeligt, på stemplet skal ringen vendes så at dette spor vender ned mod bunden af stemplet. Jeg antager endvidere, at selve udformningen af dette spor også har betydning, idet at det ideelle vil være at afkastedybden tilpasses stemplets yderdiameter eller stempel/cylindertolerancen, for at sikre at der ikke opbygges et olietryk indvendigt i ringsporet.Således en mængde konstruktiv information om Total Seal stempelringene, hvorhos en alvorlig fejl nu må være afdækket. Jeg kan nu anbefale disse stempelringe, ud fra de giver motoren forbedret kompression og mindre varmebelastning, fordi at der ikke trykkes gas ned mellem cylinder og stempel, dette er fakta som kan registres her kort tid efter ibrugtagningen. Det interessante bliver så at erfare om den flerdobbelte holdbarhed eller levetid opnås dermed.Mvh. Kurt Aggesen d. 27.05.2013